Let’s face it – we have a long way to go before we design a better world!

What am I talking about? About the ecological transformation that our civilization is currently undergoing, of course! A transformation on the quality of which the future of our entire planet will depend. Changes start in the minds, from which they then radiate into all areas of life.

Watching the pace of this transformation can sometimes give rise to severe frustration and deep doubt as to whether we, as a species, will be able to avoid a collision with reality, which is coming at us like a train with no brakes. That is why we at Perfecta have decided that we will not just be passive observers of the change but will become its driving force. We would rather act than wait!

That’s why we created Perfecta’s green growth policy, which we called GoGreen. We wrote about it some time ago. In short, it maps the actions we are taking to reduce our carbon footprint as an organisation.

Total design

One of the most salient points of the GoGreen policy, is the modification of our approach to design. Design, which includes not only the creation of furniture or coffee corners, but also the layout of all processes related to production, shipping, and other areas of our business. This approach can be called ‘total design’, as it permeates the whole of Perfecta and goes well beyond the narrow definition of the word ‘design’.

This totality is encapsulated in something called the golden rule of the 3Rs – Reduce, Reuse, Recycle. These three words perfectly describe our philosophy.

Reduce

The first ‘R’ encompasses reducing the environmental impact of our products as early as the design stage, which is not only the creation of plans for the device, but also the selection of suitable raw materials from which it will be made. Some types of material can be characterised by the proportion of the recycled plastic used. By considering them in the design process, we can reduce the use of chemically synthesised materials, making production more sustainable. Of course, we know that the proportion of recycled plastic components is limited by quality requirements, e.g., regarding the strength or colour of the part. In this regard, we avoid compromise, although we still have our own ways of maintaining the desired strength using less material.

Magic? No, Perfecta.

When choosing materials, we also consider the energy required to produce them. We know exactly what carbon footprint each of the raw materials generates and we take measures to keep it as small as possible. You can read more about how we do it here: “Carbon footprint of Perfecta’s products”.

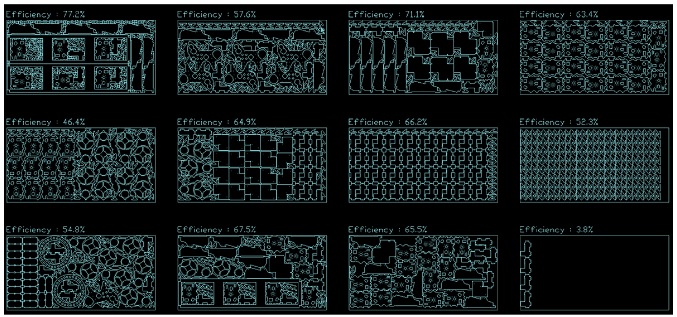

Nesting

Another element we take care of to keep our carbon footprint as small as possible is proper nesting.

But what exactly is it? It is a concept connected with two elements of our golden role of 3Rs – reducing the use of raw materials and reusing saved material. In short, it is a way of arranging the components to be cut or punched on a sheet in such a way as to minimise the loss of unused material. This is particularly important in the production of, for example, racks or tobacco dispensers, where we make extensive use of cutting and punching techniques.

We don’t want to brag, but we “can into nesting”, resulting in 15% of materials saved! This is a reduction of more than one-sixth in the amount of raw materials that need to be extracted, processed, and transported. This action alone has a visible impact on reducing our carbon footprint, and it is, after all, just one element of our GoGreen policy!

Reuse

“Don’t lose it, reuse it!” is a catchphrase by Rocky, one of the characters in the ‘Paw Patrol’ cartoon, that perfectly illustrates this element of our philosophy. Following the example of one of our children’s idols, we create our furniture to be durable and as repairable or reusable as possible. We have already touched on the arguments for choosing durable display furniture in our blog entry “Reuse in retail – how to be green, save money, and sell more?”

We think about this at the design stage, for example by considering the impact of the chosen material on the durability and use of the product. The quality and technology of the assembly and finish of the furniture are other aspects that are at the heart of our actions to make our products as durable as possible.

And how do we know that we have reached our goal? From the users, of course! But customers satisfied with the quality of Perfecta products are the last link in the chain. Before our furniture reaches its destination, it undergoes a series of rigorous tests in conditions equivalent to those that might take place in a commercial space.

One such test is the testing of the opening system of one of our REVO shelving units. For three weeks, non-stop, 24 hours a day, a hydraulic arm opened and closed its flaps. It has made more than 350,000 movements during this time, simulating almost 10 years of normal use. And to make it more realistic, instead of a sterile laboratory, the test site was the car park in front of our company headquarters.

And that is why we can vouch for the quality and durability of our products!

The quality and durability that translate into a longer life of the retail furniture, which in turn reduces the need to replace it with a new one. This is also facilitated by the possibility of replacing components, such as worn shelves in a rack. Each of our furniture pieces includes instructions on how to replace components efficiently and safely. These components are not only moving parts, such as shelves, but also pushers, lighting, power supplies and more.

Rocky the Dog would be proud!

Recycle

Recycling is the third component of our golden rule of the 3Rs.

It’s last but not the least. On the contrary, even sustainable production generates waste, so recycling is a must! We know the ins and outs of waste processing and we know that it’s not enough to just put it in the right colour container.

Therefore, to make the waste generated by Perfecta easier to recycle and dispose of, we divide it into as many as twenty-two types! We sort plastics alone into eleven categories: PVC hard, PVC soft, polyamide (PA), PMMA (Plexiglas), PS (HIPS), polypropylene (PP), polyethylene (PE), polycarbonate (PC), PET, ABS, and film. Wow…

This makes our operation not only more environmentally friendly, but also more economical, as it reduces the cost of waste collection by the treatment facility. In addition to this, our GoGreen policy is to generate no mixed waste at all by 2025.

But that’s not all! A separate issue is the waste resulting from the processing of injected components. We do not transport it to a processing plant but return it directly to the manufacturer. This ensures that our waste is reprocessed into components that will be reused in our production.

Pretty clever, isn’t it?

And when, after many years, the furniture we have produced finally reaches an end of its life, its disposal will not be a problem. We have thought about this moment too, marking the individual components of our products to indicate the type of material they are made of. Such information makes it easier for the end user to recycle them properly. In addition, all retail furniture manufactured by Perfecta Retail Furniture comes with a label with a QR code that opens a link to a digital version of their assembly, operation, and disposal instructions.

Designing the future

As I have written before – we have a long way to go before our civilization changes its mentality and correlates our interests with those of the planet. All the more a reason not to waste time! We at Perfecta are already taking action to make our children’s future the best it can be. We strive to ensure that this fragment of reality, for which we are responsible, is designed in the best possible way!